What we do

We detail, fabricate, and install structural steel and metal work structures.

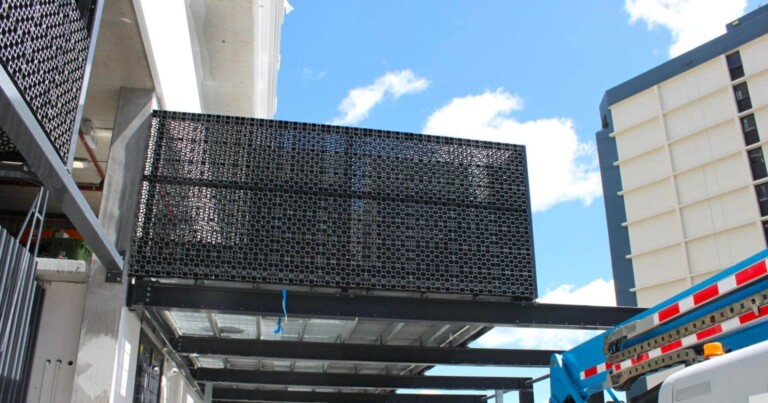

At Watkins Steel, we combine the latest 3D technology with advanced robotics to produce a variety of steel structures with unparalleled accuracy. Specialising in small structural steel, metalwork, urban artscapes, architectural designs, and refurbishment jobs, we have the experience and technological capabilities to provide first-class steel products and services in a timely manner. Our range of services also includes steel detailing and 3D laser scanning. Our experience, skills, and technological capabilities in the fabrication and construction of structural steel and metalwork structures mean that we ensure the efficient execution of project work each and every time!

Product lifecycle

Our integrated line of advanced robotics combines the benefits and abilities of:

Process & Fabrication

Delivering Steel Solutions with Precision

Process & Fabrication

Delivering Steel Solutions with Precision